A comprehensive guide to the revolutionary solid-state battery technology transforming electric vehicles in 2026

After years of promises and delays, solid-state batteries have finally arrived on public roads in 2026. This breakthrough technology, long considered the “holy grail” of energy storage, is set to revolutionize electric vehicles with faster charging times, longer ranges, and enhanced safety. From motorcycles already delivering to customers to major automakers preparing demonstration fleets, the future of electric mobility is here.

What Are Solid-State Batteries?

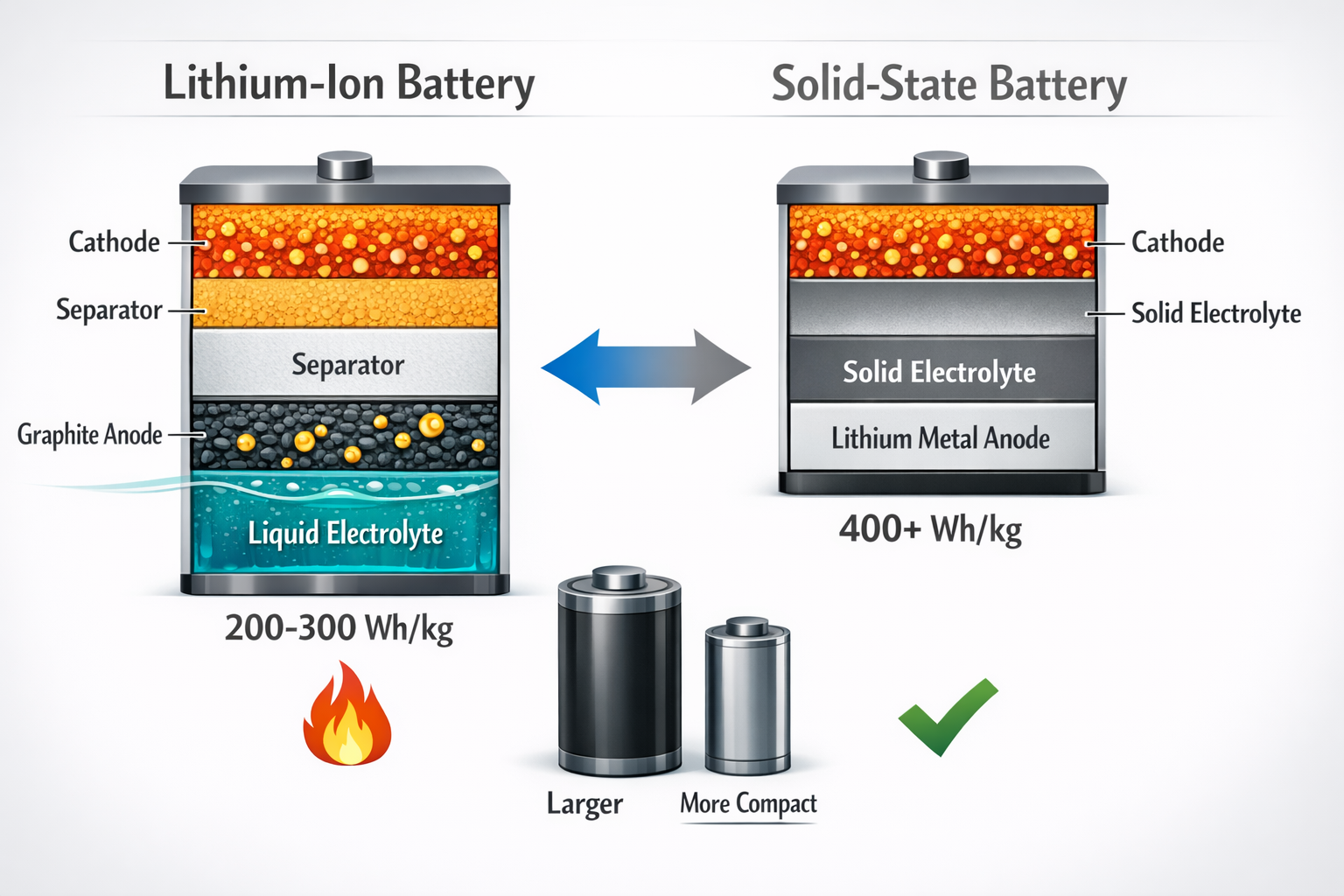

Solid-state batteries represent a fundamental shift from conventional lithium-ion technology. While traditional batteries use liquid or gel electrolytes to transport ions between the cathode and anode, solid-state batteries employ a solid electrolyte material. This seemingly simple change unlocks a cascade of performance improvements and safety benefits.

The concept dates back to the 1830s when scientist Michael Faraday first discovered solid electrolytes. However, practical applications remained elusive for nearly two centuries. In 2017, John Goodenough, the co-inventor of lithium-ion batteries, unveiled a breakthrough solid-state glass battery that reignited industry interest. Now, in 2026, multiple companies are delivering production-ready solid-state battery systems to the market.

How Solid-State Batteries Work

Traditional lithium-ion batteries can be visualized as a “rocking chair,” where lithium ions move back and forth between two electrodes through a liquid electrolyte. The charging and discharging process completes as these ions shuttle from the positive pole to the negative pole and back again.

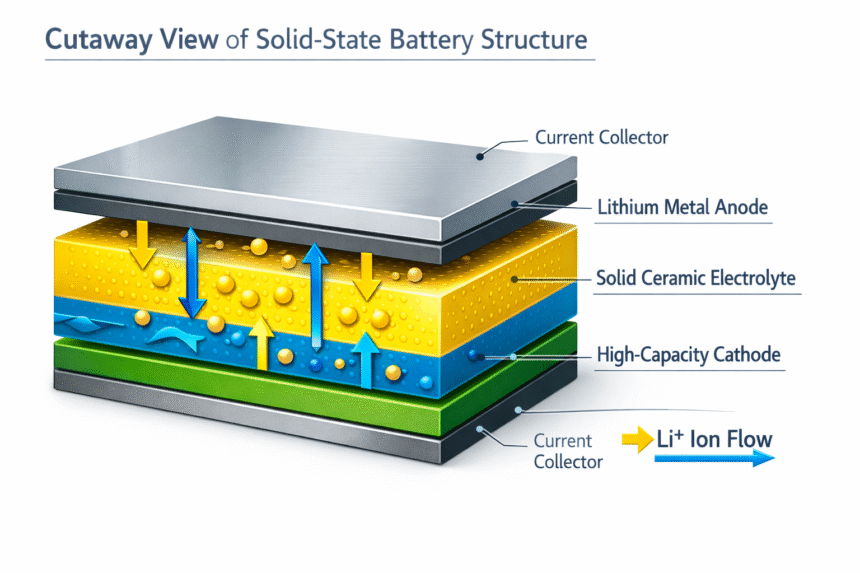

Solid-state batteries eliminate the liquid electrolyte entirely. Instead, they use solid materials such as ceramics, polymers, or glass compounds to conduct ions. This solid electrolyte acts as both an ion conductor and a physical separator between the electrodes, preventing short circuits while enabling efficient energy transfer.

The solid electrolyte allows manufacturers to use lithium metal anodes instead of lithium-embedded graphite. This change significantly reduces the battery’s overall size and weight while increasing energy density. Traditional batteries require diaphragms and liquid electrolytes that occupy nearly 40% of volume and 25% of mass. Solid-state designs eliminate these components, creating more compact and efficient energy storage systems.

Advantages of Solid-State Batteries

Higher Energy Density

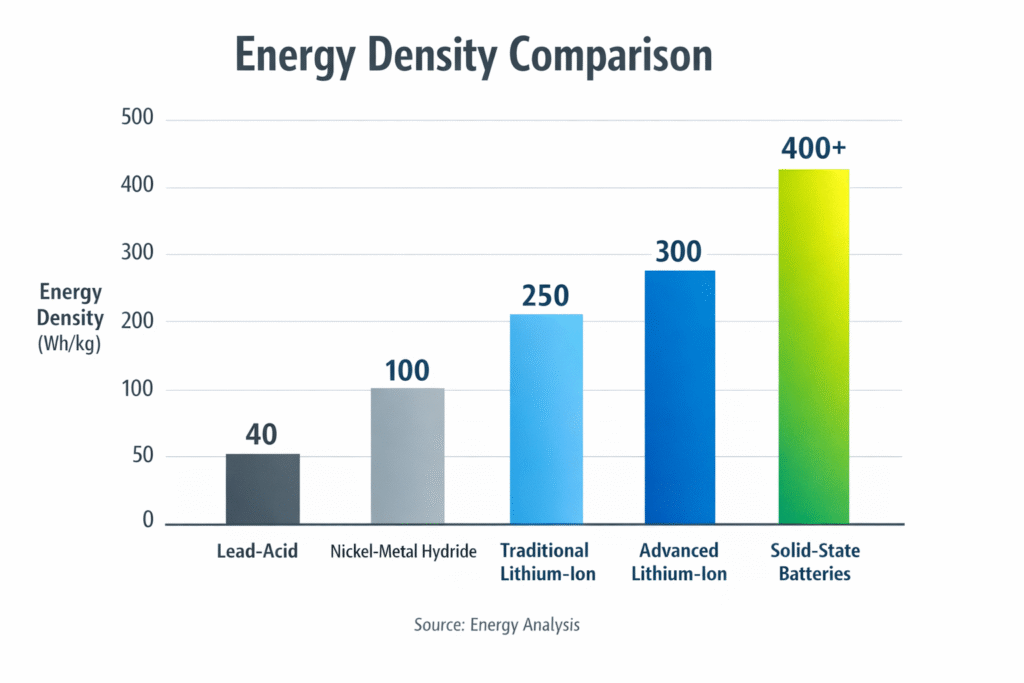

Energy density measures how much energy a battery can store relative to its weight. Current lithium-ion batteries used in electric vehicles typically achieve 200-300 watt-hours per kilogram (Wh/kg). Solid-state batteries promise dramatically higher figures, with some manufacturers claiming 400 Wh/kg or more.

Finnish startup Donut Lab reports achieving 400 Wh/kg with their production-ready solid-state batteries now powering Verge Motorcycles. Chinese automaker Dongfeng claims 350 Wh/kg in batteries scheduled for production in September 2026, while Factorial’s technology demonstrates over 390 Wh/kg. These improvements translate directly into longer driving ranges without adding vehicle weight.

Faster Charging Times

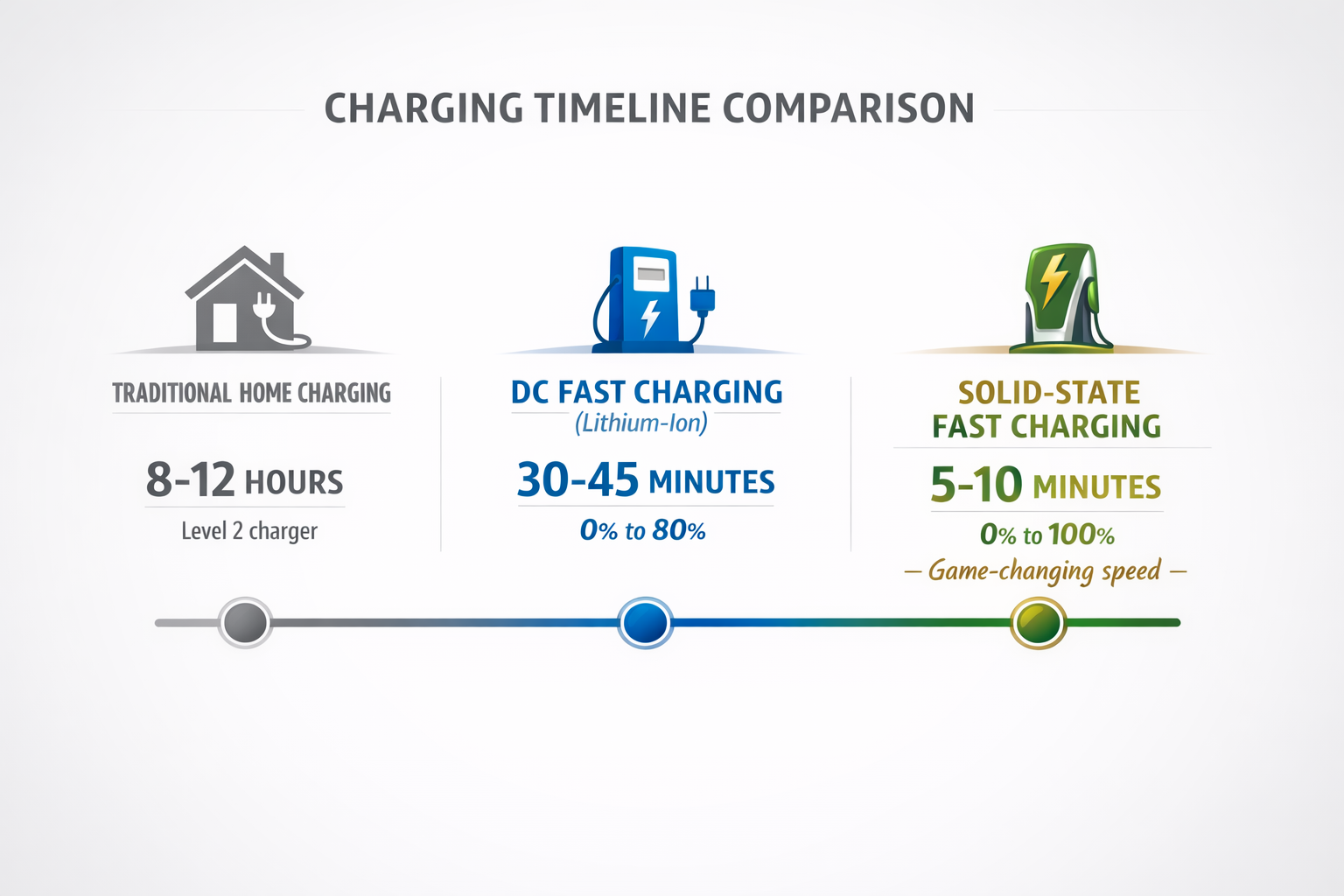

Charging speed represents one of the most significant advantages of solid-state technology. Donut Lab claims their batteries can fully recharge in as little as five minutes, offering approximately 60 kilometers of range per minute of charging. This performance far exceeds conventional lithium-ion batteries, which typically require 30-45 minutes to reach 80% capacity on fast chargers.

Factorial’s semi-solid-state cells can charge from 15% to 90% in just 18 minutes at room temperature. The solid electrolyte enables more efficient ion transfer and handles higher charging currents without degradation. This capability could eliminate one of the primary barriers to electric vehicle adoption: charging anxiety.

Enhanced Safety

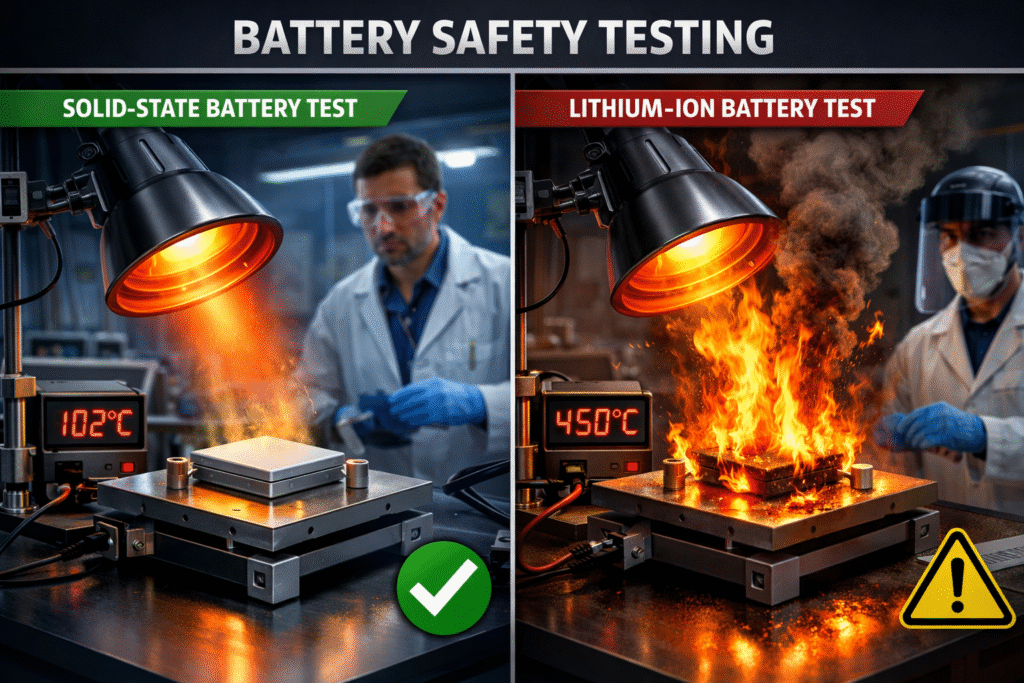

Safety improvements represent perhaps the most crucial benefit of solid-state batteries. Traditional lithium-ion batteries contain flammable liquid electrolytes that can leak, overheat, and potentially catch fire in a process called thermal runaway. While modern battery management systems have significantly reduced these risks, the danger cannot be completely eliminated with liquid-based designs.

Solid-state batteries eliminate flammable liquids entirely. The solid electrolyte is non-combustible, dramatically reducing fire risk. Donut Lab’s batteries have been tested at temperatures exceeding 100°C while retaining over 99% capacity with no thermal runaway. This inherent safety allows for more flexible battery placement in vehicles and reduces the need for heavy thermal management systems.

Extended Lifespan

Battery longevity significantly impacts electric vehicle total cost of ownership. Conventional lithium-ion batteries typically last for a few thousand charge cycles before capacity degrades noticeably. Manufacturers often recommend limiting charging to 80% to preserve battery life.

Solid-state batteries promise dramatically longer lifespans. Donut Lab claims their batteries can sustain up to 100,000 charge cycles with minimal capacity fade. This means owners could fully charge and discharge the battery daily for decades without significant performance loss. The batteries can also be charged to 100% without the degradation concerns associated with liquid-based systems.

Better Temperature Performance

Electric vehicles using lithium-ion batteries often struggle in extreme temperatures. Cold weather can reduce range by 30-40%, while high temperatures accelerate battery degradation. Solid-state batteries perform more consistently across temperature extremes.

Donut Lab reports their batteries retain over 99% capacity at temperatures as low as -30°C. Dongfeng tested their solid-state batteries at -22°F (-30°C) where they maintained over 72% capacity. This temperature resilience makes electric vehicles more practical in regions with harsh climates.

Challenges and Limitations

Manufacturing Complexity

Despite recent breakthroughs, solid-state battery production remains more complex than conventional battery manufacturing. The solid electrolyte requires precise fabrication to ensure consistent ion conductivity. Creating reliable contact between the solid electrolyte and electrodes presents engineering challenges.

Current manufacturing processes cannot simply retrofit existing lithium-ion production facilities. Companies must develop entirely new production lines, which requires significant capital investment. This manufacturing complexity contributes to higher initial costs and limited production volumes.

Higher Initial Costs

Solid-state batteries currently cost significantly more than lithium-ion batteries. Some estimates suggest they are three to four times more expensive. Materials for solid electrolytes, particularly certain ceramics and specialized polymers, remain scarce and costly.

However, costs are expected to decline rapidly with mass production. Research from 2024 projected that solid-state battery prices could reach $140 per kilowatt-hour by 2028 in the best-case scenario, making them competitive with advanced lithium-ion batteries. As production scales up through 2026 and beyond, economies of scale should drive prices down significantly.

Technical Hurdles

Several technical challenges still require attention. Solid electrolytes can be brittle, potentially developing cracks during charging cycles that increase resistance and reduce performance. Different solid electrolyte materials (sulfides, oxides, polymers, halides) each have distinct advantages and drawbacks, and no single material has emerged as the clear standard.

Recent research from South Korea’s KAIST has shown promising solutions. Scientists discovered that redesigning the battery’s internal crystal structure using divalent anions can improve lithium ion movement by up to four times without adding expensive metals. Such innovations demonstrate that technical challenges are being systematically addressed.

Solid-State Batteries in Production: 2026

Verge Motorcycles and Donut Lab

Estonia-based Verge Motorcycles made history in early 2026 by becoming the first vehicle manufacturer to deliver production motorcycles powered by all-solid-state batteries to customers. Their 2026 model lineup, including the TS Pro and Ultra, features batteries developed by Finnish startup Donut Lab.

The standard Verge motorcycle offers a 217-mile city range matching previous lithium-ion models. However, the long-range version extends this to an impressive 370 miles (600 kilometers) in the same physical space. Charging time drops to under 10 minutes, though Verge intentionally slows charging slightly to allow riders adequate break time.

Donut Lab unveiled their technology at CES 2026 in Las Vegas, demonstrating that solid-state batteries have moved beyond laboratory prototypes into real-world applications. The company is now engaged with over 200 original equipment manufacturers (OEMs) exploring integration of their battery technology.

Chinese Manufacturers

China has established itself as a leader in solid-state battery development. In January 2026, China introduced the world’s first national standard for solid-state EV batteries, providing clear definitions and classifications that will help standardize the industry.

Dongfeng Motor Corporation announced plans to begin commercial production of semi-solid-state batteries in September 2026. These batteries promise over 620 miles (1,000 kilometers) of range on China’s CLTC testing cycle, translating to approximately 400+ miles on the more stringent EPA cycle. The company has been testing solid-state batteries since 2022, initially installing them in 50 prototype E70 electric sedans.

Battery giants CATL and BYD, which together control over 50% of the global EV battery market, aim to begin small-scale solid-state battery production around 2027, with mass production targeted for the end of the decade. A new solid-state electrolyte pilot project backed by CATL, SAIC Motor, and state-owned enterprises recently received regulatory approval, designed to accelerate development of all-solid-state EV batteries.

Stellantis and Factorial

Stellantis and Massachusetts-based Factorial have validated a semi-solid-state battery cell with energy density exceeding 390 Wh/kg. The companies announced in late 2024 that a demonstration fleet of all-new Dodge Charger Daytona vehicles equipped with Factorial’s solid-state batteries will hit the road in 2026.

This initiative builds upon the $75 million investment Stellantis made in Factorial in 2021. The demonstration fleet will enable validation of the technology in real-world driving conditions across the STLA Large platform, which supports brands including Jeep, Dodge, Chrysler, Alfa Romeo, and Maserati. The platform is designed to support up to two million vehicles globally, making it ideal for large-scale solid-state battery deployment.

In September 2025, Factorial’s battery cells were used in a road test where a modified Mercedes EQS drove over 745 miles (1,200 kilometers) on a single charge, demonstrating the real-world potential of solid-state technology.

Japanese Automakers

Japanese automakers Toyota, Nissan, and Honda are all developing solid-state batteries with production timelines around 2028. Toyota has signed a joint development agreement with Sumitomo Metal Mining to mass-produce cathode materials for all-solid-state batteries. Sumitomo will begin production in early 2028, initially prioritizing Toyota before opening to other manufacturers.

Toyota aims to become the first automaker to incorporate all-solid-state batteries into production electric vehicles. The company plans to initially deploy the technology in hybrid vehicles, potentially doubling the electric-only driving range of popular models like the RAV4 and Prius.

Honda stated that its solid-state batteries could potentially be 50% smaller, 35% lighter, and 25% cheaper than current lithium-ion batteries. The automaker plans to install solid-state batteries in production vehicles sometime in the second half of this decade.

Impact on Electric Vehicle Market

Range Anxiety Elimination

Range anxiety remains one of the primary barriers preventing consumers from purchasing electric vehicles. Solid-state batteries could effectively eliminate this concern. With energy densities approaching 400 Wh/kg and beyond, electric vehicles could achieve ranges of 500-600 miles or more on a single charge, exceeding most gasoline-powered vehicles.

Even more importantly, the combination of extended range and ultra-fast charging means drivers could add hundreds of miles of range in just minutes. This charging experience would closely mirror the convenience of refueling a gasoline vehicle, removing a major psychological barrier to EV adoption.

Vehicle Design Flexibility

The compact size and enhanced safety of solid-state batteries provide automotive designers with unprecedented flexibility. Batteries can be packaged in smaller spaces or distributed throughout the vehicle structure without the same fire risk concerns. The lighter weight of solid-state batteries also improves vehicle efficiency and handling characteristics.

Reduced thermal management requirements mean less space dedicated to cooling systems, allowing for more passenger room or cargo capacity. The improved safety profile may also reduce insurance costs and regulatory compliance burdens.

Cost Reduction Potential

While solid-state batteries currently cost more than lithium-ion technology, the long-term cost trajectory appears promising. The extended lifespan means batteries may outlast the vehicle itself, eliminating replacement costs. Higher energy density reduces the total amount of battery material needed for a given range, potentially lowering material costs.

Simplified thermal management and enhanced safety can reduce other vehicle systems costs. As production scales up over the next few years, manufacturing costs should decline significantly. Honda’s estimate of 25% lower costs compared to lithium-ion batteries suggests solid-state technology could make electric vehicles more affordable for mainstream consumers.

Applications Beyond Electric Vehicles

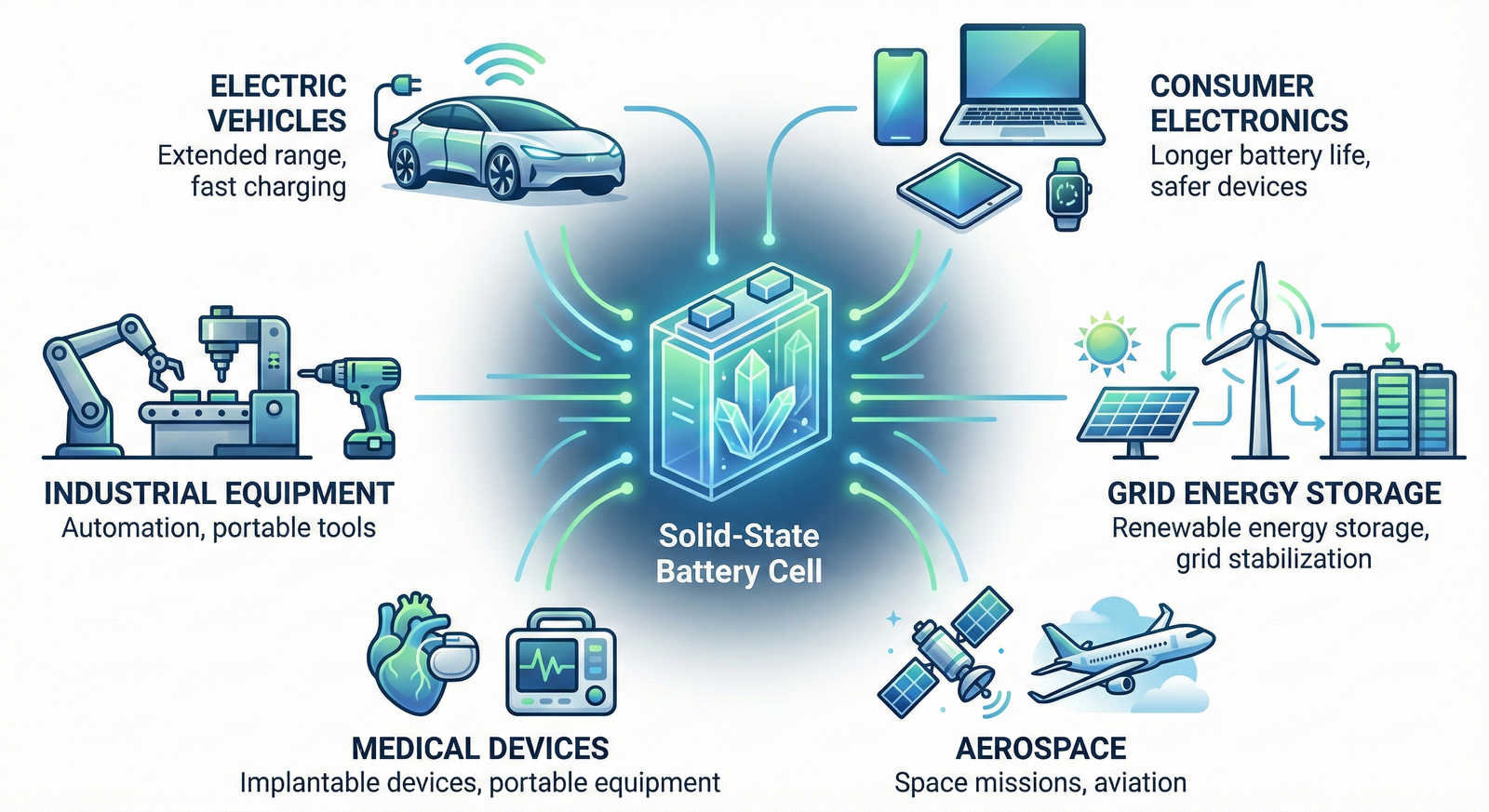

Consumer Electronics

Solid-state batteries promise significant improvements for smartphones, laptops, tablets, and wearable devices. Higher energy density means devices can run longer between charges while maintaining the same size and weight. Alternatively, manufacturers can reduce device thickness and weight while keeping current battery life.

The enhanced safety of solid-state batteries addresses growing concerns about battery fires in consumer electronics. ProLogium partnered with Darfon Energy Tech at CES 2026 to introduce solid-state battery solutions targeting e-bikes and other high-frequency consumer products.

Grid Energy Storage

Renewable energy sources like solar and wind require robust energy storage systems to balance supply and demand. Solid-state batteries offer exceptional reliability and extended operating life, making them ideal for storing large amounts of energy for grid applications.

The long cycle life of solid-state batteries means they can charge and discharge daily for decades without significant degradation. This longevity dramatically improves the economics of grid-scale energy storage, accelerating the transition to renewable energy.

Aerospace and Medical Devices

The aerospace industry has shown significant interest in solid-state batteries. In 2022, Japan’s Hitachi Zosen Corporation launched a test mission demonstrating solid-state batteries operating successfully in space. The batteries’ wide operating temperature range and enhanced safety make them ideal for harsh environments.

Medical devices, particularly implantable devices like pacemakers, can benefit from solid-state battery technology. The non-flammable nature, compact size, and extended lifespan make them safer and more reliable for critical healthcare applications.

The Road Ahead

Timeline for Mass Adoption

While 2026 marks the arrival of solid-state batteries in production vehicles, mass market adoption will unfold gradually over the next several years. Initial deployments will likely focus on premium and high-performance vehicles where higher costs can be absorbed more easily.

Industry experts project solid-state batteries will appear in premium or higher-performance models around 2027 or 2028, before reaching mass-market electric vehicles at or slightly after the end of the decade. Chinese manufacturers may accelerate this timeline given their aggressive development schedules and government support for electric vehicle technology.

Standardization Efforts

China’s introduction of the first national standard for solid-state EV batteries in January 2026 represents an important step toward industry standardization. The standard defines solid-state batteries by electrolyte type, conducting ion, and application, providing clarity for manufacturers and regulators.

The draft sets a strict allowable weight-loss rate of no more than 0.5% to qualify as a solid-state battery, more stringent than earlier industry proposals. This standardization will help ensure consistent quality and performance across different manufacturers. Additional standards covering other aspects of solid-state battery technology are expected to follow.

Conclusion

The transition to solid-state technology is more than just an incremental upgrade; it is the definitive closing of the gap between internal combustion and electric power. While the road to mass-market ubiquity still requires navigating manufacturing hurdles, the 2026 rollout proves that the “laboratory dream” is now a road-ready reality.

By solving the historical trade-offs between safety, speed, and longevity, solid-state batteries have effectively set a new gold standard. As this technology matures, it won’t just change how we drive—it will redefine our entire relationship with portable and grid-scale energy, cementing 2026 as the year the electric revolution finally lost its limitations.

FAQs:

Which vehicles currently use solid-state batteries in 2026?

As of early 2026, Verge Motorcycles (TS Pro and Ultra models) are the first consumer vehicles delivering to customers with all-solid-state batteries. In the automotive sector, Dodge is deploying a demonstration fleet of Charger Daytonas equipped with Factorial’s solid-state technology, and Dongfeng is testing fleet vehicles with plans for mass production later in the year.

How much faster do solid-state batteries charge compared to current EVs?

They are significantly faster. While traditional lithium-ion batteries typically take 30–45 minutes to charge to 80%, solid-state batteries can achieve similar or better charges in 5 to 15 minutes. For example, Donut Lab’s technology claims to add approximately 60km of range for every minute of charging.

Are solid-state batteries safer than standard lithium-ion batteries?

Yes. The primary safety advantage is the elimination of flammable liquid electrolytes found in traditional batteries. Solid-state batteries use non-combustible solid electrolytes (ceramic, glass, or polymer), which drastically reduces the risk of fires or thermal runaway, even if the battery is punctured or overheated.

4. Why are solid-state batteries considered the ‘Holy Grail’ of EV technology?

They are called the “Holy Grail” because they solve the three biggest hurdles of electric vehicles simultaneously: Range Anxiety (by packing more energy into less space), Charging Speed (near-instant refueling), and Safety (removing fire risks). They also promise much longer lifespans, potentially outlasting the vehicles themselves.

Will solid-state batteries make electric cars more expensive?

Initially, yes. Currently, the manufacturing cost is estimated to be 3–4 times higher than traditional lithium-ion batteries due to complex production processes and material scarcity. However, costs are projected to drop rapidly as mass production scales up, with estimates suggesting price parity with current batteries by roughly 2028–2030.